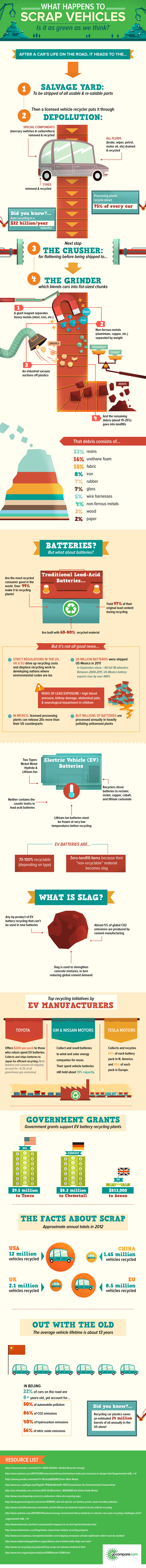

Here is a pretty good overview of measures that the industry is taking to make sure that electric vehicle batteries will be recycled completely and efficiently. Battery recycling dramatically lowers the lifecycle pollutant footprint of electric vehicles because a large part of the overall footprint comes from extracting rare earth metals and manufacturing new batteries. If we can recover those metals through recycling cost-effectively, then that part of the process can be negated in future generations of vehicles. Since the developed world has a good track record with traditional lead-acid vehicle batteries, 99% recovery, I don’t see why it would be different for more advanced, lithium ion EV batteries.

Category Archives: -Uncategorized-

Is hydrogen fuel cell technology a non-starter?

This article was written by www.asm-autos.co.uk, the UK’s leading vehicle salvage agents and experts in the ‘value my car’ market.

The majority of manufacturers are now producing ranges of electric plug-in vehicles (EVs), with the Government investing millions in supporting this young and growing market, giving alternative technologies significantly less press.

However, in America, manufacturers have recently moved into hydrogen fuel cell technology, or H2, which could yet provide the cleanest, most energy efficient fuel solution ever developed.

However, with electric making leaps forward, is H2 technology a case of too little, too late?

How does H2 work?

H2 technology successfully converts hydrogen gas and oxygen into energy via an in-car fuel cell, powering the motor to drive the car. This differs from electric technology as it utilises hydrogen fuel which is stored under pressure in a tank, similar to the way petrol is stored in traditional cars.

One of the advantages of fuel cell technology is that it is fully scalable; if you require more power, you can increase the size of the cell; large fuel cells can therefore be used to power buildings and very small cells used to power electrical equipment like MP3 players.

Environmental benefits

In comparison to conventional electric technology, H2 is better for the environment because it does not produce the level of emissions associated with generating electricity at power stations.

Hydrogen can be derived from natural gas in the atmosphere or produced from water using a process called electrolysis; the only by-product of the process is water vapour and a small amount of hydrogen. This abundant fuel source also gives countries the opportunity to develop independent energy supplies, reducing their reliance on the Middle East.

Energy efficiency

Both fuel cell and electric technology are more energy efficient in comparison to gasoline engines because they send a much higher percentage of energy towards powering the vehicle, with the latter losing energy in heat and friction during combustion.

While earlier prototypes offered direct hydrogen combustion, burning the gas to create energy in the same way petrol is burnt in conventional vehicles, this was a far less efficient energy process.

Toyota’s energy efficiency trial, which tested a range of alternative hydrogen technologies, including hydrogen to electric, saw H2 come out on top as the cleanest and most energy efficient.

Availability and cost

In America, a limited range of H2 cars are available, including the Hyundai Tucson Fuel Cell, the Toyota HCFV-adv and the Mercedes-Benz F-Cell. Toyota have also recently released a new hydrogen fuel cell prototype, the FCV-R.

Like any new technology, fuel cells cars are expensive to produce, and the current range of models therefore come at a high price premium. However, provided that manufacturers are able to build production volumes, these costs will fall in the medium term.

Performance

Manufacturers hope to produce H2 vehicles which perform as well as well current petrol models. Although they offer slightly lower acceleration, newer models are likely to provide quicker, more powerful alternatives as the technology develops.

Offering the quietness and smoothness of an EV with fewer moving parts and simplified design, they are more robust than conventional petrol cars and have the potential to be longer-lasting. While the current crop of vehicles have longevity of 60,000 miles, the next generation are likely to last 3.5 times longer, the same as a conventional car.

Fuel cells can also be replaced relatively easily, involving much less costly processes than repairing a conventional petrol engine.

Safety

Hydrogen has garnered a reputation for being explosive following a major airship disaster in Hindenburg in 1937. However, hydrogen is no more unsafe than petrol, which is highly flammable and explosive, but has safely fuelled the passenger car market since its inception.

The current range of H2 vehicles are fitted with effective systems to reduce risk of explosion, and the technology is therefore as safe as any other on the market.

Infrastructure

In America, lack of hydrogen fuelling infrastructure has restricted sales of fuel cell cars hugely. Although California has plans for the construction of 100 hydrogen stations, it will be a while until the consumer market catches on.

In the longer term, petrol fuel stations could easily be converted to accommodate hydrogen gas, underground pipes or trucks used to distribute the fuel. With this in mind, the US Government has developed the H2USA programme, joining forces with manufactures, agencies, gas suppliers, and fuel cell providers.

In the UK the Government has responded by setting up the UKH2Mobility scheme, collaborating with major players from the gas, car manufacturing and related support industries to develop the technology further:

“This country has a number of world-class companies that are developing exciting technologies in both the hydrogen energy and automotive value chains and it is vitally important that we identify what is required to make these cars a realistic proposition for UK consumers,” said UKH2Mobility’s Mark Prisk.

“UKH2Mobility will bring together industry expertise to establish the UK as a serious global player in the manufacture and use of hydrogen fuel cell electric vehicles and the supporting infrastructure,” he added.

Race to the top

With electric technology already advancing across America and Europe, and governments investing heavily in electric charging infrastructure, some feel that H2 has emerged a little too late to make a significant impact on the car market, and could be brushed aside.

Manufacturers have already invested hundreds of millions in developing commercialised electric and hybrid vehicles, with the UK Government backing electric technology heavily. There is also the chance that a rival technology will be created, with Peugeot recently unveiling a car that can be successfully powered by air.

However, provided that car manufacturers and governments put energy efficiency first, there is no reason why hydrogen cannot become the next prime source of automotive fuel. It’s certainly an exciting time to be involved in the automotive industry.

Electric Car Servicing and Maintenance

Guest post by: Eric Muhanji

Petrol and diesel-powered cars ruled the previous century. However, electric cars are entering new markets every year because of their low fuel (electricity) costs and relatively low maintenance costs compared to gasoline-powered cars. Also, these cars are environment friendly and are famously coined as ‘green cars.’ Electric cars are being produced all around the world today due to increasing gasoline costs and also environmental issues. Most customers purchase these cars for their lower handling costs and also the ‘zero emission’ factor.

Most electric cars are serviced by authorized service centers recommended by the dealers from whom you buy the car. These cars do not contain combustion engines and operate with the help of batteries and an electric motor. Let us try to understand more about what kind of service and maintenance is required for electric cars.

Service and Maintenance

Electric cars contain less parts than gasoline-driven cars. Therefore, the maintenance costs of these cars are significantly lower. The batteries of electric cars last for approximately 100,000 miles. This is the only big maintenance issue. Other than this, there are no major problems with electric cars that require a lot of extra spending.

Electric cars contain an electric motor that drives the car with some six to seven more parts that help rotate the tires. Estimates suggest that maintaining an electric car can cost one-third the amount it takes to maintain a normal gasoline-driven car.

The batteries are the most expensive parts in an electric car. Batteries lose their ability to hold a charge over time. This is true for all kinds of batteries. After some 100,000 miles, you may need to change your batteries. These can get so expensive sometimes that buying a new electric car would seem a better option. However, most manufacturers offer warranties on batteries.

The motor brushes in an electric car wear out over time due to constant friction. These brushes may need replacement after nearly fifty to sixty thousand miles. It is also good to carry out periodic checks to make sure the electric components and minor parts are all fine.

The maintenance of electric cars compared to other types of cars is significantly lower due to the fact that these cars do not contain complex engines with parts like pistons or valves.

Conclusion

It is wise to have a proper understanding and knowledge of electric cars before purchasing one. Make sure to ask the dealer in detail about things that need regular checks in these kind of cars. Also, inquire about servicing options and requirements. Electric car servicing definitely requires less money than a gas-powered car. Finding a good auto mechanic who can help you with repairs of your electric car can take some time. However, mechanisms of electric cars are very simple and relatively easy to understand. This is the reason most mechanics can handle repairs of these cars with relative ease.

Author’s bio:

Eric Muhanji writes for ServicingStop.co.uk – a nationwide online automotive MOT and Service network with over 1,000 garages in the UK.

Hydrogen Fuel Cell Buses Coming On Line in Cleveland

Hydrogen powered vehicles can convert hydrogen into mechanical energy in two ways, through combusting the fuel to create power at the wheels or converting the hydrogen to electricity through a fuel cell, which sends the power to an electric motor. So while technically, you don’t need to plug in a fuel cell electric vehicle, it is still very much an electric car. I actually had the chance to ride in a fuel cell electric SUV at the Seoul Metropolitan Government last summer. These vehicles show promise as a compliment or substitute for traditional electric drivetrains, since hydrogen fuel can be transported with minimal energy loss, and they allow for quick refueling. However, the technology is still very, very expensive compared to plug-in electric vehicles.

Cleveland has not been known for much since Lebron James left, but in the past year, the city’s Regional Transit Authority has been partnering with NASA Glenn Research Center to develop a hydrogen powered fuel cell bus fleet. This technology provides a great opportunity for Cleveland to showcase their commitment to sustainable, clean transportation. However, right now, each bus costs $2 million dollars, in addition to the hydrogen fueling infrastructure requirements.

INDUSTRY NEWS

Cleveland RTA launches hydrogen buses

Metro Magazine

January 16, 2013

The Greater Cleveland Regional Transit Authority (RTA), in coordination with NASA Glenn Research Center, launched a hydrogen bus project in Cleveland.

Customers on various routes may now experience a quieter and greener ride, powered by hydrogen, not diesel. This vehicle began carrying customers in January 2013.

RTA is the first transit system in Ohio — and one of the few in the nation — to produce its own hydrogen fuel using electrolysis, a process that separates water into hydrogen and oxygen.

The 40-foot bus has a capacity of 57 passengers and will be in service between six and eight hours daily on various RTA routes. The bus operates with nearly twice the fuel-efficiency as diesel-fueled bus; and is much quieter as well. The joint project between RTA and Glenn supports the development of new technologies and clean and renewable energy sources.

The hydrogen-fueled bus is on loan from United Technologies Corp. (UTC Power) and the electrolyzer is on loan from NASA Glenn. The entire program, which includes the fueling system and bus, is valued at $3 million. RTA Board members approved a $50,000 investment in this project, which pays for the installation and use of fueling equipment.

This goal of this collaboration between RTA and NASA Glenn is demonstrating the safety, fuel-efficiency, economy and reliability of hydrogen production and fueling using electrolysis. The fuel cell bus is powered by hydrogen and does not produce harmful emissions — the only emission is water vapor.

Link:

The World’s First Electric Monster Truck: Bigfoot No. 20

For some reason, this reminds me very much of my childhood days in the driveway with my remote control monster truck. Odyssey Battery, which is a subsidiary of Enersys,and Bigfoot teamed up to create the world’s first full-size electric monster truck, dubbed, creatively, Bigfoot No. 20. It may not have the ear-drum-shattering-power of your traditional Bigfoot or Gravedigger, but judging by the above video, it gets the job done crushing old Ford Tauruses (Tourusii?).

Here are the specs:

EnerSys, parent company of Odyssey Battery, supplied 36 drycell batteries (upgraded versions of a standard car battery) to provide juice to a specially designed motor that produces 350 horsepower and 850 pound-feet of torque – far less than the 1,000+ hp produced by today’s average monster truck. Instead of roaring to life, the electric Bigfoot No. 20 quietly whirs around the parking, which in the video makes it sound like a life-sized Power Wheels, before laying waste to a couple of down-and-out Ford Taurus sedans. Like the monster trucks you can see at just about any stadium around the country, this Bigfoot has tires that make crushing cars easy and four-wheel steering for better maneuverability. In all, the truck’s 36 batteries add an extra 1,375 pounds, and while the system includes on-board battery chargers, there is no word on how long such a job would take. – Autoblog

Press Release:

ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck, World’s First Electric Monster Truck

READING, Pa. (Nov. 27, 2012) – ODYSSEY® battery by EnerSys, a primary sponsor of the 2012 BIGFOOT 4×4, Inc. monster truck team, provided ODYSSEY® batteries to power the world’s first electric monster truck: the ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck.

Each of the 36 ODYSSEY® PC1200 batteries that power the ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck weighs 38.2 pounds, but provides 1,200 five-second pulse hot cranking amps (PHCA), as well as 540 cold-cranking amps (CCA), 78 minutes of reserve capacity and 400 cycles of deep cycle capability at 80 percent depth of discharge (DOD).

The ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck carries a custom-designed 2012 fiberglass body and includes a battery-powered electric motor, which was designed and built by Dennis Berube of Phoenix to wield 350 horsepower and 850 foot-pounds of torque. Three banks of 10 ODYSSEY® batteries power the engine for a total of 360 Volts. The additional six ODYSSEY® batteries power the brakes and steering systems. Other custom features include onboard battery chargers and variable-speed programmable speed controller.

“We’ve been sponsoring BIGFOOT® monster trucks for almost 10 years,” said Dave McMullen, director of commercial marketing for specialty and UPS markets at EnerSys®. “The punishing conditions of a monster truck race are a perfect demonstration of ODYSSEY® batteries at their rugged best. We are particularly excited to be part of the world’s first battery-powered monster truck, and are proud of BIGFOOT 4X4, Inc.’s confidence in our batteries that they play such a

“ODYSSEY® batteries have helped our team to win more than 20 monster truck championships,” said Jim Kramer, vice president of research, technology and driver development of BIGFOOT 4X4, Inc. “We’re happy to have ODYSSEY® batteries as a partner in the development of the ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck. Developing a custom electric monster truck is part of our efforts to keep up with ever-changing technology. For now, the ODYSSEY® Battery BIGFOOT® No. 20 Monster Truck will be used in static displays and parades, but as we become more experienced with the electric power unit, battery maintenance, controller adjustments, drive lines and weather, our fans may just see it perform car crushes or even compete in monster truck shows.”

About EnerSys®

EnerSys®, the world leader in stored energy solutions for industrial applications, manufactures, distributes and services reserve power, motive power and starting, lighting and ignition (SLI) batteries, chargers, power equipment, and battery accessories to customers worldwide. SLI batteries are used for trucks and buses, passenger cars, boats, personal watercraft, ATVs, motorcycles and garden tractors. The company also provides aftermarket and customer support services to its customers from more than 100 countries through its sales and manufacturing locations around the world. For more information about EnerSys® and its ODYSSEY® batteries, visit www.enersys.com or www.ODYSSEYbattery.com.

About BIGFOOT 4×4, Inc.

Since its inception in 1975, BIGFOOT, The Original Monster Truck®, has gone on to achieve worldwide notoriety, and spawned an entire family of BIGFOOT monster trucks that have pioneered the growth of the monster truck industry. Created by St. Louis-area contractor Bob Chandler and his wife Marilyn in 1975 as a promotional tool for their Midwest Four Wheel Drive business, the BIGFOOT fleet has captured 29 National Championships, set numerous world records for monster trucks, and travelled to more than 26 countries. In 2009, BIGFOOT was named one of the “Top 5 Marketing Vehicles of All Time.” Since 1975, more than 20 BIGFOOT vehicles have been constructed, and today the team campaigns seven (soon to be nine) BIGFOOT monster trucks full-time in North America, in addition to one based full-time in England. The team achieves in excess of 4 million live impressions each year and will have over 800 appearance days in 2012 with more expected in 2013. Over half-a-million BIGFOOT toys are sold every year. Visit the team online at www.bigfoot4x4.com

The Road of the Future

We spend a lot of time here at OnElectricCars.com talking about the innovations of the vehicles on the road, but we neglect to mention what is happening in the pavement itself. If electric vehicles become more mainstream, there will be numerous opportunities to change the way we drive and fuel up. Could the road charge itself up with photovoltaics or solar-thermal and recharge moving electric vehicles through induction? Could intelligent networks drive our cars across the country for us? The infographic below indicates these crazy ideas are possible, and even being tested around the world right now:

The Road to the Future – created by the team at Car Loan 4U

Infographic tags:

the road of the future pavement technology roadway technology recycled plastic road eco-pave dynamic paint road glow in the dark road markings antique electric car wind powered lights wireless electric vehicle charging inductive power transfer solar roads solar panel roads solar powered car piezoelectric energy roads intelligent highways